The Clayton Mine has quite a history. It’s located on Kinnikinic Creek in Custer County, near the ghost towns of Bonanza and Custer. Significant deposits of lead-silver ore were discovered in the mountain slopes above Kinnikinic Creek in the 1870s. The Idaho Mining and Smelter Company, based in Omaha, Nebraska, built a 30-ton capacity smelter and a company store in 1880, in what would later become the town of Clayton, just a few miles away.

An article in the July 17, 1880, issue of the Yankee Fork Herald reported this about Clayton:

“Wednesday forenoon we reached the mouth of Kinnikinic, distant from Bonanza 30 miles. Here we found a streak of business. Everything was bustle and stir. Gen. W.W. Lowe was busy directing the affairs of the Salmon River Mining and Smelter Co. This is an Omaha organization, composed of men of both capital and enterprise, who are inaugurating extensive works for mining and smelting the ores of Kinnikinic and adjacent camps. C.B. Rustin is president of the company and W.W. Lowe general manager and treasurer. Men were coming on every trail to get employment or to locate. Wages are $2.50 with board $3.50 without. A town will be built fast as materials can be had. H.D. Jaquish is putting up a storeroom and warehouse, and in a few days will move his goods up from East Fork. Everything is moving briskly as possible under the circumstance. Supplies have yet to come up from East Fork and Challis by pack trains, but the company will have a road completed to East Fork in time for the machinery.”

The Clayton Mine was highly successful. By 1937, a waterwheel-powered electrical plant was built to generate the mine’s electricity for operating machinery and equipment. From 1927 until its closure in 1986, the mine extracted over 2 million tons of ore and produced more than 86 million lbs. of lead, 28 million lbs. of zinc, 1.6 million lbs. of copper, and 400,000 lbs. of silver. The ore was very high quality. The value of these metals is estimated at about $350 million in today’s dollars.

However, the good times were not without setbacks. In 1983, an earthquake caused a significant increase in water seepage into the deeper levels of the mine. Powerful pumps were installed, which had to remove over 2 million gallons of water daily.

The Clayton Mine closed in 1986 after almost 60 years of operation, primarily due to low metal prices which made the mine unprofitable. The site is currently owned by CMX Gold & Silver Group of Calgary, Canada. It is estimated that the tailing piles contain at least 1 million tons of unprocessed ore due to its low grade. Advances in mining technology could make processing this ore feasible, and there is consideration of restarting mining operations. However, the site remains inactive as of 2025.

Photo courtesy of the Clayton Area Historical Association

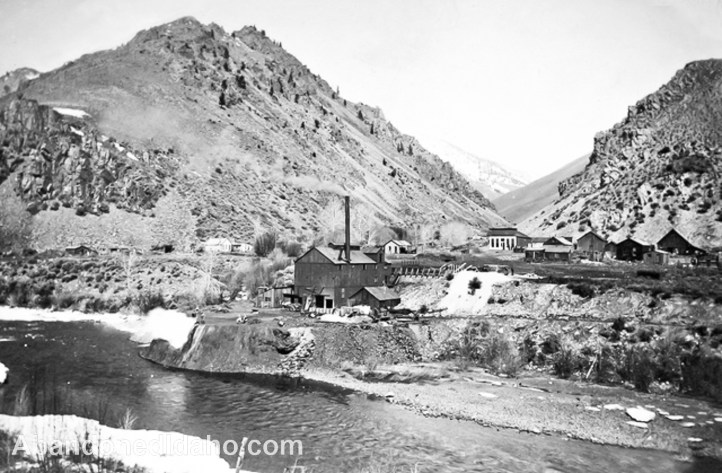

Ore from the Clayton Mine was transported a short 2 miles down to this smelter in the town of Clayton. A smelter refines ore by heating the ore in giant blast furnaces to the point where it melts and the metal separates from the waste material. During the smelter’s first 2 years of operation, coke had to be transported all the way from Pennsylvania at a great cost. Coke is produced by heating coal to extremely high temperatures. This burns off impurities in coal, converting into almost pure carbon, which burns much hotter than coal. To reduce expenses, locally produced charcoal was substituted, with a massive 7 million lbs. produced annually. Using a similar process, wood is converted into charcoal in giant kilns for the same reason, although using charcoal is not as efficient as using coke. The smelter is the building in the center of the photo. It no longer exists.

Photo courtesy of the Clayton Area Historical Association

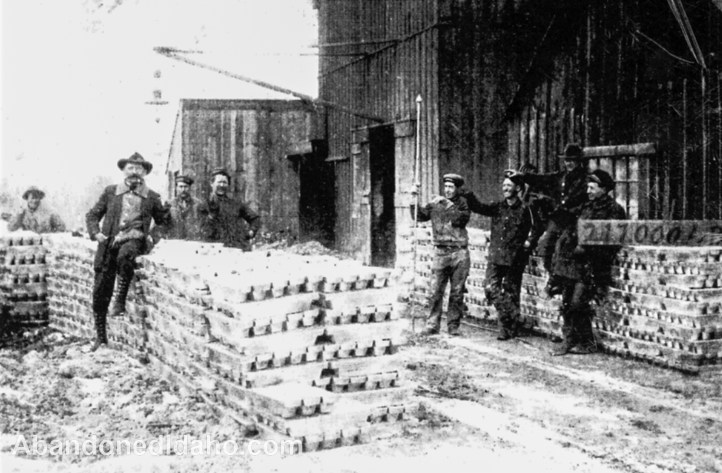

This photo from 1912 shows lead-silver bars ready to be shipped by wagon to the railroad spur at Mackay. Each bar weighed 107 lbs. Most hard rock mines in Idaho consisted of underground shafts and tunnels with hoists or ore cars on tracks to bring the ore to the surface. A mill would then pulverize the ore into a “concentrate” which resembled sand. Ore concentrate is partially processed in order to make the subsequent smelting more efficient. The concentrate from the Clayton Mine was then shipped to a smelter, sometimes as far away as Utah, where gold, silver, or lead was separated from the unusable material. The Clayton Mine, conveniently, had this smelter that was a short distance away.

Public domain photo

This is what the Clayton lead and silver mine looks like today. This view is looking towards the town of Clayton where the smelter was located. Tailing piles can be seen on the far side of the canyon.

Photo credit: Steve Cobbley

In 1940 the mill produced over 4 tons of lead and silver concentrate per day. In 1942 additional milling equipment was added to produce zinc concentrate. By 1960, the Clayton Mine produced 93% of the ore in Custer County containing lead, silver, zinc, copper, and gold. It was a busy operation, with the mine running 6 days per week and the mill operating 7 days per week. In 1974, it was the only large-scale producer of lead and silver outside Shoshone County in northern Idaho, where the Hecla Mine was operating in Burke.

Photo credit: Larry Myhre

The tall building is the mill where the chunks of ore were processed into concentrate. By 1981 this mill had the capacity to process 250 tons of ore per day.

Photo credit: Steve Cobbley

The long structure pictured here most likely covered either a conveyor belt or tracks used by ore cars to transport the ore dumped by the headframe on the right to the mill on the left. This allowed the conveyor belt to operate during times of heavy snowfall.

Photo credit: Steve Cobbley

Much of the machinery and equipment that was not salvaged when the mine was shut down has been left to meet its ultimate fate of rusting away until nothing remains.

Photo credit: Steve Cobbley

A peek inside their building reveals what looks like the changing room. This would have been where miners climbed out of their dirty work clothes, showered, and washed off the sweaty grime from their subterranean world.

You can leave a comment by scrolling down to the very bottom of this post to where you see “Leave a comment“. Please subscribe to our blog if you would like to be notified of new posts and/or new comments.